Can Materials Help Prevent Disease Transmission? A Material Science Perspective

As health, hygiene, and material innovation continue to converge, the question of whether materials themselves can play a role in preventing disease transmission is more relevant than ever. Beyond traditional cleaning and disinfection, advances in surface engineering, polymers, and antimicrobial additives are enabling materials to actively resist or neutralise microbial threats. In this article, we answer some of the most common and emerging questions around this growing field—drawing on research, real-world examples, and industry-leading technologies.

What are antimicrobial materials and how do they work?

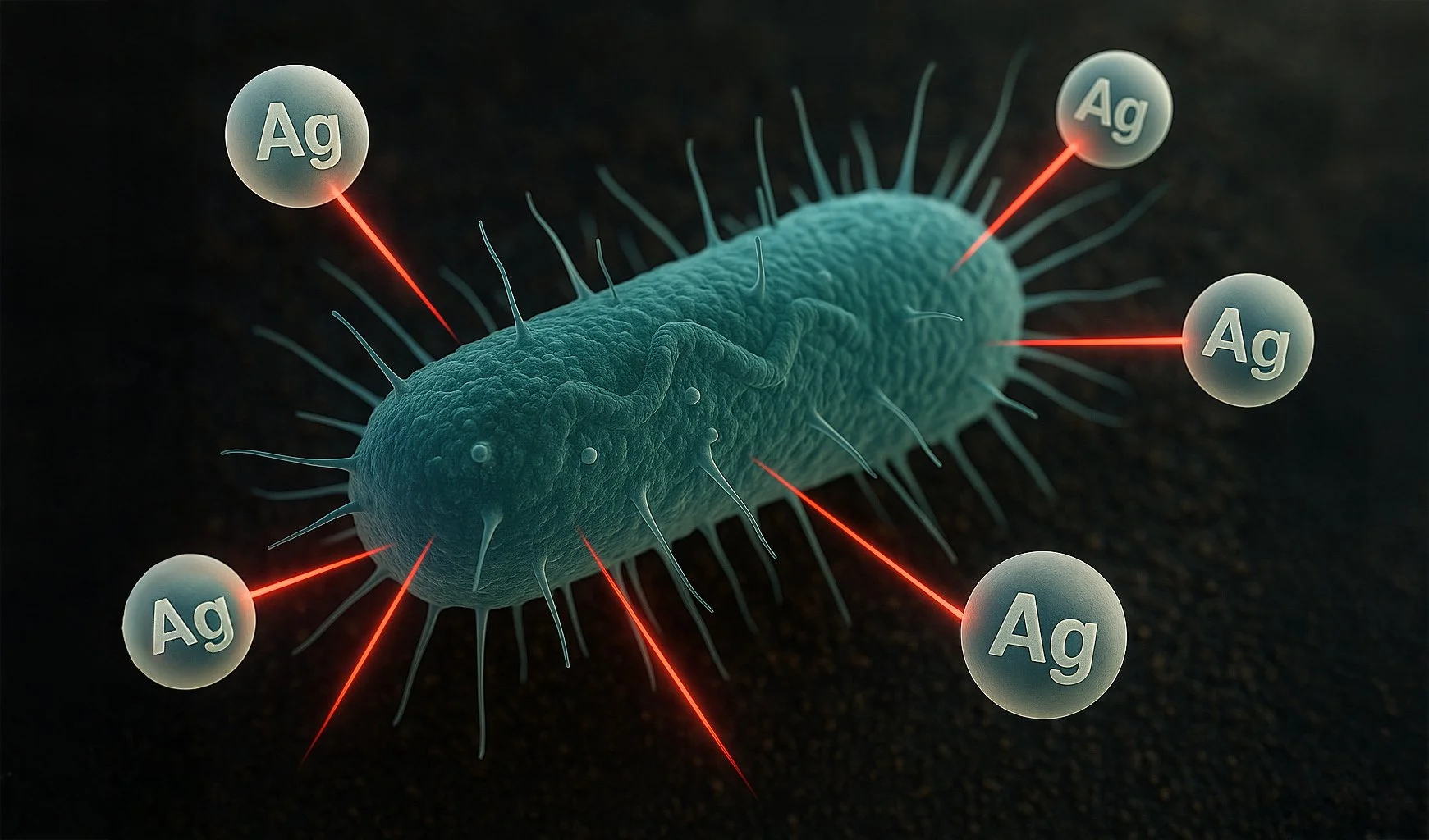

Antimicrobial materials are engineered to inhibit the growth or survival of microorganisms such as bacteria, fungi, and certain viruses. This is typically achieved by incorporating antimicrobial agents—like silver ions, zinc compounds, quaternary ammonium compounds, or bio-based actives—directly into the substrate of plastics, coatings, textiles, and foams.

These agents disrupt key biological functions in microbes, such as protein synthesis or membrane integrity, preventing reproduction or causing cell death. Unlike disinfectants, antimicrobial materials provide continuous protection for the life of the product, without requiring reapplication. For example, silver ions bind to bacterial enzymes and DNA, halting vital processes and rendering the organism inactive.

These materials are particularly useful in high-touch or hygiene-critical environments, such as hospital beds, public transport seating, and wearable electronics, where microbial accumulation can occur quickly and traditional cleaning is not always practical or frequent enough.

Where are these materials used today?

Antimicrobial materials are already integrated into a wide range of sectors and products, including:

Healthcare: Hospital bed rails, privacy curtains, catheter tubes, and medical device housings often include antimicrobial surfaces to reduce hospital-acquired infections (HAIs).

Public transport: Seating, handrails, tray tables, and overhead bins in buses, trains, and aircraft use antimicrobial coatings to manage hygiene between deep cleans.

Consumer electronics: VR headsets, wearables, and shared gaming controllers benefit from embedded antimicrobial additives to manage skin flora and odour-causing bacteria.

Workplaces and public buildings: Touchscreens, keypads, shared desks, and lift buttons are increasingly being treated to manage microbial transfer.

Textiles: Uniforms, sportswear, PPE, and home furnishings are often treated with antimicrobial and odour-control technologies for freshness and hygiene.

Suppliers like Addmaster (Biomaster), Microban, BioCote, and Polygiene lead the way in providing antimicrobial solutions to OEMs and manufacturers across these sectors.

Which microbes can antimicrobial materials target?

While no antimicrobial surface is 100% effective against all pathogens, many technologies are tested and proven to reduce the growth of common and potentially harmful organisms, including:

Staphylococcus aureus, including MRSA

Escherichia coli (E. coli)

Fungi and moulds such as Aspergillus niger

Certain enveloped viruses (depending on the active agent and material compatibility)

Efficacy is commonly tested under controlled conditions using international standards such as ISO 22196 (for plastics and non-porous surfaces) or ASTM E2180 (for polymeric materials).

How do antimicrobial materials differ from disinfectants?

Disinfectants are chemical agents applied intermittently to kill microorganisms on surfaces. They are typically fast-acting but temporary. In contrast, antimicrobial materials are engineered with continuous microbial resistance that lasts the entire life of the product. They do not replace cleaning routines but instead complement them by reducing microbial build-up between cleanings.

This passive mode of action is ideal for settings like transport cabins, hospital environments, or space missions, where cleaning access may be limited or infrequent.

Are antimicrobial additives safe for long-term use?

Yes, when used within regulated limits. Most commercially available antimicrobial additives are backed by toxicological safety data and approved for use in consumer and industrial applications. For example:

Silver-based additives are approved under the EU Biocidal Products Regulation (BPR) and the U.S. EPA Treated Articles Exemption.

Additives are incorporated in such low concentrations that they do not pose risks to users, and they are typically locked within the material matrix to prevent leaching.

Many products have passed skin irritation and sensitisation tests (e.g., OECD guidelines) for long-term contact with human skin or clothing.

Nonetheless, manufacturers must comply with regional regulations and clearly communicate the intended use and performance limitations of treated materials.

Can these materials help reduce global disease transmission?

They can contribute meaningfully to reducing surface-borne transmission in shared spaces. While antimicrobial materials are not a standalone solution to infectious disease control, they are part of a multi-layered approach to hygiene, particularly in high-traffic, high-contact environments.

By reducing the microbial burden on surfaces between cleaning cycles, these materials can lower the risk of fomite-based transmission—especially in settings like schools, airports, gyms, care homes, and mass transport systems.

In the context of pandemics or emerging diseases, antimicrobial materials can help reinforce public health efforts, giving infrastructure designers and employers an additional layer of passive defence.

What does the future hold for antimicrobial materials?

As global attention on hygiene and surface health continues to grow, the development of next-generation antimicrobial technologies is accelerating. Key trends include:

Bio-inspired surfaces that mimic sharkskin or lotus leaves to physically repel or prevent microbial adhesion without chemicals.

Smart materials that activate antimicrobial function in response to moisture, temperature, or pH.

Sustainable actives derived from natural sources such as enzymes, peptides, or plant extracts.

Multifunctional coatings that combine antimicrobial protection with anti-fingerprint, anti-static, or self-cleaning properties.

Data-driven materials integrated with sensors to detect microbial growth or contamination events in real-time.

These innovations are likely to play an increasing role in future public infrastructure, autonomous systems, and wearable technologies.

Further Reading

Addmaster – Biomaster Antimicrobial Additives

https://www.addmaster.co.uk/technologies/biomaster

Silver ion technology for plastics, coatings, and textiles across transport, medical, and consumer sectors.

Polygiene – Odour Control and Antimicrobial Textile Treatments

https://www.polygiene.com/technologies/

Advanced textile technologies that extend freshness and reduce bacterial growth in clothing and soft furnishings.

BioCote – Antimicrobial Technology in Public Spaces

https://www.biocote.com/environments/

Integration examples in offices, transport hubs, and healthcare facilities.

Microban – Antimicrobial Innovation Blog

https://www.microban.com/blog

Insights into the latest trends, science, and applications of antimicrobial product protection.

EPA – Treated Articles Exemption

https://www.epa.gov/pesticide-registration/prn-2000-1-applicability-treated-articles-exemption-antimicrobial-pesticides

Guidelines for making antimicrobial claims in materials under U.S. law.

ISO 22196 – Measurement of Antibacterial Activity

https://www.iso.org/standard/54431.html

International standard used to assess antibacterial performance on non-porous surfaces.

World Health Organization (WHO) – Hygiene and Infection Prevention

https://www.who.int/teams/integrated-health-services/infection-prevention-control

Global policies and strategies for preventing infections across healthcare and public settings.