The Age of Intelligent Textiles with Materials Built for Longevity and Performance

Textiles shape the way we live. They define comfort, identity, safety, and performance in ways that often go unnoticed until they fail. For decades, textile development has been dominated by cycles of trend and consumption, with materials engineered primarily for appearance, cost and speed. But the world has changed. Consumers are asking new questions. Industries are raising expectations. Policymakers are pushing for accountability. And textiles, once treated as simple commodities, are now emerging as a complex frontier of material science, sustainability and technology.

The global textile sector is entering a period of profound reinvention. This shift extends far beyond fashion and apparel. It touches healthcare, transportation, architecture, industrial design, sports, and public infrastructure. Everywhere textiles are used, pressures are rising: to last longer, perform better, generate less waste, use fewer resources and support healthier environments. This is reshaping how materials are designed, manufactured, maintained, and experienced, and is driving a new era of innovation grounded in chemistry, circularity and performance engineering.

In this landscape, textiles are no longer passive fabrics. They are becoming dynamic materials systems, capable of responding to environmental conditions, resisting degradation, enhancing user confidence and performing functions that once required separate technologies. The transformation is not cosmetic. It is structural.

The Material Challenge Behind Modern Textiles

The textile industry faces a series of deeply rooted challenges, technical, environmental and behavioural. Traditional fibres and fabrics struggle under the weight of modern expectations, particularly in areas involving durability, cleanliness and lifecycle performance.

Many textiles degrade rapidly under everyday conditions. Colours fade, fibres break down, and fabrics lose shape and softness. Microbial buildup contributes to odour, staining and surface damage. Sweating, friction and repeated stress accelerate wear. The result is an unspoken reality: most textiles are discarded long before they reach the end of their mechanical lifespan. They fail aesthetically or hygienically, not structurally.

This is compounded by another systemic issue: washing. Frequent laundering consumes vast quantities of water and energy while accelerating fibre wear and releasing microplastics into the environment. Conventional chemical finishes, when applied to improve odour control or performance, often wash out after a handful of cycles, providing short-lived benefits while contributing to wastewater burdens.

These issues expose an underlying truth. The textile industry does not simply need better fabrics; it needs smarter materials. Fibres and constructions designed to address degradation, odour, contamination and performance loss at their source. Only innovation at the material level can reconcile comfort, function and sustainability in a meaningful way.

New Vectors of Innovation Reshaping the Textile Landscape

The reinvention of textiles is being driven by several converging innovation pathways. Each reflects a different dimension of what modern materials are now expected to achieve.

High-Performance and Adaptive Textiles

Performance fabrics have moved far beyond athletic wear. Moisture-regulating fibres, odour-control technologies, antimicrobial treatments, temperature-responsive yarns and abrasion-resistant constructions are becoming standard across industries. These improvements help textiles remain closer to their original state throughout their use, a key factor in extending lifespan and reducing replacement cycles.

Sustainable and Bio-Based Materials

Sustainability is no longer peripheral. Regenerated cellulose, recycled polyesters, bio-based polyamides and natural-synthetic hybrid blends are becoming viable substitutes for conventional fibres. Yet sustainability is not just about material origin; it is about the entire lifecycle. The most future-ready textiles combine renewable feedstocks with performance properties that minimise waste throughout their service life.

Circularity and Lifespan Engineering

The move toward a circular economy places pressure on manufacturers to design textiles that last longer, shed less, and can be reused or recycled more effectively. This requires deeper collaboration between fibre producers, chemical innovators, designers and waste processors. Circularity is no longer a downstream concern, it is a design framework that begins with fibre chemistry.

Antimicrobial and Hygiene-Focused Treatments

Hygiene has become a design parameter in its own right. Built-in antimicrobial technologies help stabilise textiles against microbial factors that cause odour, staining and premature degradation. By controlling these impacts, antimicrobial textiles reduce laundering frequency, improve user experience and maintain value for longer. This is particularly critical in healthcare, hospitality, transportation and high-touch public settings.

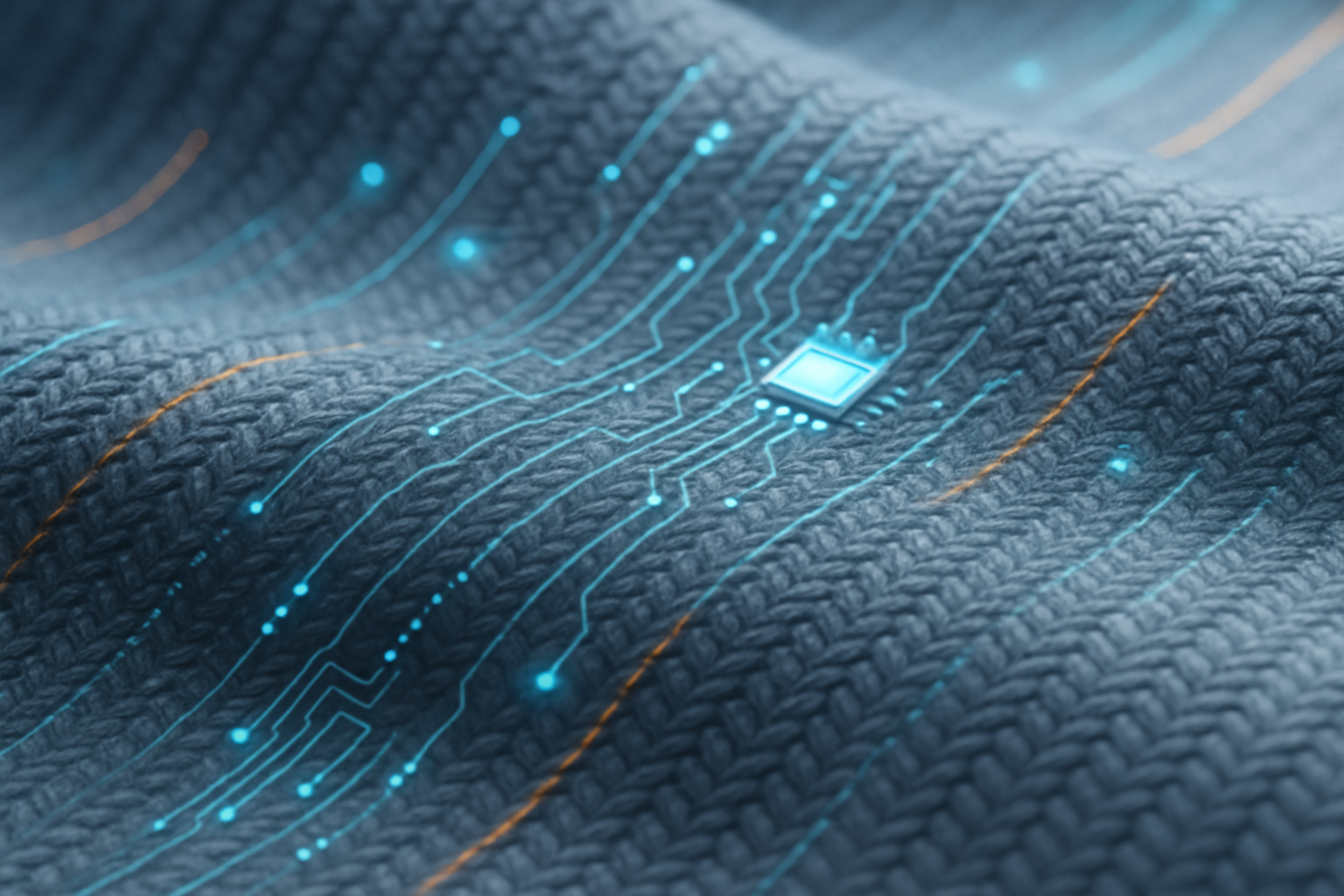

Digital and Intelligent Textiles

The next frontier includes materials embedded with sensors, conductive fibres, thermal mapping systems and adaptive responses to environmental changes. These innovations are still emerging, but they signal a broader shift: textiles are becoming platforms for data, interactivity and dynamic performance, not just passive layers between the body and environment.

These vectors are not isolated. They are merging into a new materials ecosystem where performance, cleanliness, sustainability and intelligence reinforce one another.

Antimicrobial Technologies and the Rise of Hygiene-Centric Design

Odour, sweat, humidity and microbial growth remain some of the most stubborn contributors to textile degradation. When microbes accumulate on fibres, they alter colour, weaken structure, trap smells and reduce comfort. Many garments are discarded not because they are worn out, but because they no longer feel fresh.

Antimicrobial technologies support hygiene-centric design by slowing the growth of the microbes responsible for these effects. When integrated into fibres or polymer coatings, they help textiles stay cleaner between washes, maintain appearance for longer and deliver a more stable sensory experience.

This stability matters. It reduces laundering frequency, which lowers environmental impact. It improves user confidence in high-touch environments. And it helps manufacturers create products that retain their value over extended periods.

However, integration must be precise. Effective antimicrobial design depends on compatibility with fibre chemistry, durability across washing cycles, and regulatory compliance. Technologies must work with, not against, the structural properties of the textile. In this sense, antimicrobial technologies are no longer simply additives; they are engineered components of an evolving materials system.

Supply Chains, Circularity and Lifecycle Redesign

Material innovation is reshaping the textile supply chain from end to end. Fibre producers must develop chemistries that support both enhanced performance and recyclability. Manufacturers need processing methods that preserve functionality while reducing energy and chemical use. Brands are expected to design garments for longer lifespans, modular repair, and clearer end-of-life pathways.

At the consumer level, behaviour is also shifting. People are increasingly aware of environmental impact, water use and material longevity. Products that last longer, stay fresher between washes and maintain functional performance align closely with these expectations.

Circularity is not achievable without material stability. A garment that loses functionality after ten washes cannot be part of a viable circular economy. Innovation is therefore not only about new fibres or finishes but about engineering textiles that degrade more slowly, shed less microplastic, and preserve their value for as long as possible.

Antimicrobial technologies play a subtle but important role here: by reducing microbe-driven degradation, they support lifespan engineering, an emerging field in which materials are designed for long-term stability rather than short-term use.

What the Next Decade of Textiles Will Become

The textiles of the next 10–20 years will not resemble those of today. They will be smarter, cleaner, more resilient and more deeply integrated into systems of sustainability and circularity. The industry is moving toward textiles that:

Combine renewable chemistry with multi-functional performance

Maintain structural integrity and sensory quality far longer than current standards

Support reduced washing and lower environmental impact

Integrate hygiene, comfort and durability at the material level

Blend physical textiles with digital sensing and adaptive behaviours

Are designed with clear end-of-life pathways from the outset

This transformation will not come from any single innovation. It will be the result of a new mentality, one that treats textiles as engineered materials rather than disposable commodities.

Material innovation has become the engine of this shift. Whether through bio-based fibres, antimicrobial technologies, recycled polymers, advanced coatings or adaptive systems, the future of textiles depends on how well we can redesign the building blocks of fabrics themselves.

A New Era for Textiles as Living Materials Systems

The reinvention of textiles is ultimately a reinvention of expectations. Performance is now measured not only at the moment of purchase but across the entire lifecycle — from wear and maintenance to longevity and disposal. The textiles that succeed in this environment will be those grounded in thoughtful material science, intelligent design and aligned sustainability ambitions.

As industries and consumers move toward higher standards of durability, hygiene and responsibility, textiles are emerging as a quiet but powerful frontier in materials innovation. The question is no longer whether textiles can evolve, but how far they can go — and how quickly we can bring these innovations into everyday life.

Material Innovation Insights will continue exploring this transformation, helping readers understand how chemistry, technology and sustainability are converging to redefine the future of textiles. The era of passive fabrics is ending. The age of intelligent, durable, performance-driven materials has already begun.

Further Reading

Smart and Sustainable: A Global Review of Smart Textiles, IoT Integration, and Human-Centric Design

https://doi.org/10.3390/s25237267Advancements in Antimicrobial Textiles: Fabrication Methods, Mechanisms and Applications

https://pubs.acs.org/doi/10.1021/acsomega.4c11356The Future of Fabric: A Comprehensive Review of Self-Powered Smart Textiles and Their Emerging Applications

https://doi.org/10.1016/j.egyr.2025.07.002Smart Textile Design: A Systematic Review of Materials and Technologies for Textile Interaction and User Experience Evaluation Methods (2025)

https://doi.org/10.3390/technologies13060251Synthetic vs. Natural Antimicrobial Agents for Safer Textiles (2024)

https://pubs.rsc.org/en/content/articlehtml/2024/ra/d4ra04519jAdvancing Antimicrobial Textiles: A Comprehensive Study Addressing Effectiveness and Safety Against Resistant Pathogens (2024)

https://doi.org/10.3390/ma17020383